World’s first flexible solar manufacturing facility to use micro-groove technology opens in the UK

Published:

Read Time: 7 mins

- Power Roll’s flexible solar film pilot manufacturing facility opens in County Durham.

- Energy Minister, Greg Hands says: “Power Roll embodies the North East’s spirit of enterprise – a company making cutting-edge green technology right here in the UK; powering growth and creating quality jobs in our industrial heartlands.”

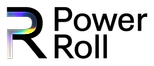

Durham, UK, [24 February 2022 13:00 GMT]: Today, Power Roll opens its solar film manufacturing facility in County Durham. It is the first facility in the world to produce low-cost, lightweight, flexible solar film using Power Roll’s patented micro-groove technology. Located on a former colliery site, the pilot manufacturing facility is a milestone in the evolution of energy, producing next-generation solar solutions to support the transition towards a sustainable energy system.

Energy Minister Greg Hands said: “Solar energy can not only slash our carbon emissions but also protect UK billpayers from expensive gas prices.

“Power Roll embodies the North East’s spirit of enterprise – a company making cutting-edge green technology right here in the UK; powering growth and creating quality jobs in our industrial heartlands.”

Emerging solutions such as Power Roll’s flexible film will enable solar to be deployed more easily in the built environment, off-grid, on vehicles and other applications where traditional silicon solar panels are too heavy or too expensive to be used. Estimates suggest that current UK commercial roof space alone could accommodate almost 100 gigawatts of solar film – equivalent to building 20,000 five megawatt solar farms.

Neil Spann, chief executive, Power Roll added: “Our mission is to dramatically increase the uptake of solar power, worldwide, and our new pilot manufacturing facility is a huge step towards delivering our vision. Our technology can make a significant contribution to tackling climate change while improving the lives of millions, worldwide, through access to low-cost clean energy.

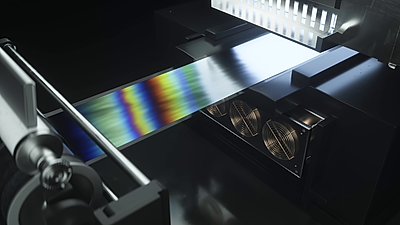

“Developed in the UK, our unique micro-groove design enables a manufacturing process that uses a roll-to-roll technique similar to many low-cost print processes in use today. We will fully demonstrate our technology at our Durham facility and will partner with large companies in the UK and overseas to globally scale up the solar film manufacturing. Countries around the world will be able to establish local manufacturing facilities to produce solar film for deployment in their own cities, towns and remote communities, creating thousands of green jobs.”

Power Roll’s approach to manufacturing solar film, which uses widely available materials and familiar production processes, yields a carbon footprint that is up to 20 times lower than silicon PV. When the film is produced at scale, manufacturing costs are forecast to be as low as a tenth of the cost of other flexible PV. Solar film can be deployed on warehouses and agricultural sheds where the roofs are not strong enough to bear the weight of traditional solar panels. Its light weight and flexibility also make it easier and cheaper to transport, bringing electricity to communities who may not otherwise have been able to access it.

Power Roll recently signed an agreement with UK-based Futurepump, a manufacturer of affordable, portable water pumps for agriculture. The partners will explore the use of Power Roll’s solar film with Futurepump’s irrigation pumping system, particularly in off-grid locations such as Africa, Southeast Asia and South America. The combination of lightweight solar film and highly efficient DC-based water pumps creates a water distribution system that is environmentally friendly, sustainable, adaptable, easy to use, and very low cost.

Power Roll’s new pilot factory, located in Jade Business Park, County Durham currently employs 34 highly skilled workers and heralds the start of a new generation of solar power; offering new opportunities for manufacturers to diversify into the burgeoning renewable energy market. Power Roll recently secured £5.8m of further equity investment; taking the total to over £20m to fund the ongoing development and scaling of its unique technology. The company has also benefitted from significant regional and national government support including four rounds of UKRI Energy Catalyst funding, worth more than £1.5 million.

Ends

Editors notes

Content:

1. How much solar do we need?

2. The roof-space opportunity

3. About Power Roll

3.1 Case studies

3.2 Recent investment

3.2.1 Quotes from investors

4. Contact for interview or further information

---

1. How much solar do we need?

UK Government’s Energy White Paper states that a low-cost, net zero consistent electricity system is most likely to be composed predominantly of wind and solar generation, whether in 2035 or 2050.

National Grid, the UK’s energy systems operator reports that we need to build 3GW of wind and 1.4GW of solar every year until 2050.

The UK’s Climate Change Committee (CCC) in its Sixth Carbon Budget report calls on the country to ‘front-load’ decarbonisation. In other words, more needs to happen in the 2020s than in the 2040s with UK electricity production reaching net-zero by 2035.

Solar Energy UK's report, Lighting the Way, calls for the government to set a target of 40GW of solar PV by 2030, which is in line with CCC net zero recommendations. To date, the UK has installed 14GW of solar PV.

2. The roof-space opportunity

Driven largely by the continued growth of online retail, warehouse space has grown dramatically over recent years. In the UK alone, the Warehousing Association estimates the total warehouse roof space to be around 420 million sq ft, and forecasts suggest the spike in online sales during 2020 alone will create demand for an additional 30 million sq ft of space.

All of this roof space offers a potential solution to expand solar capacity without using up greenfield and agricultural land. Power Roll’s estimates suggest that current UK commercial roof space could accommodate almost 100 gigawatts of solar – equivalent to building 20,000 typical 5 megawatt ground-mounted solar farms. With lightweight solar film that is cheaper to make and install, we can fully exploit the roof-space opportunity and take the pressure off the use of greenfield sites for solar farms.

3. About Power Roll

Power Roll has developed a unique, flexible, lightweight solar film capable of producing ultra-low-cost green electricity. When the film is produced at scale, manufacturing costs are as low as a tenth of the cost to manufacture compared with other flexible PV

By applying different coatings to its versatile microgroove design, Power Roll can also use the film for energy storage and to manufacture capacitors. Power Roll has an existing joint venture with Deki Electronics in India to manufacture an innovative range of capacitors with significant advantages over existing technologies.

Power Roll’s microgroove solar film is uniquely suitable for low-load-bearing rooftops, building integration, transport, portable applications, off-grid projects and IoT sensors.

In 2021, Power Roll was named by Cleantech Group as one of the ‘50 to watch’ companies taking action on climate change. Find out more…

3.1. Case studies

Futurepump

Power Roll recently announced its partnership with Futurepump to explore the use of solar film to power Futurepump’s highly efficient DC-based solar irrigation pumps to alleviate manual irrigation efforts and provide a sustainable solution for small farm irrigation.

Inseaenergy

Power Roll is collaborating with Inseaenergy to use Power Roll’s lightweight, flexible solar film in aquaculture and maritime applications.

Filia Solar

Power Roll announced its partnership with Filia Solar to explore the use of Power Roll’s solar film for solar PV-enabled window blackout blinds.

3.2. Recent Investment

In Q1 2022, Power Roll raised a further £5.8 million taking total investment in the company to more than £20 million. This equity funding comes from a combination of current and new investors and will be used to further develop pilot scale production of low cost, flexible solar film towards commercialisation.

The £5.8 million is the first phase of two stages in Power Roll’s investment round and demonstrates the market’s confidence both in Power Roll’s technology and in its applications across several large and fast-growing markets. The first phase was over-subscribed, with the second phase already launched and expected to conclude in 2022.

3.2.1 Quotes from investors

Roger Doo, Director, Kero Limited, says: “The new pilot production plant at Jade Business Park is an impressive facility. It will be a fantastic base for Power Roll to scale up and commercialise its innovative technology. Kero is proud to have been able to contribute to the Power Roll growth to date and to support its mission to open up cost-effective solar power to individuals and businesses across the globe.”

Cam Ross, CEO of Green Angel Syndicate, says: "We are so pleased to be helping Power Roll build a lighter, more flexible way for the world to generate renewable energy. Our investment in this round complements that from an earlier round, and underscores the GAS commitment to growing companies with the technology to fight climate change."

https://www.powerroll.solar

For further information or interview opportunities contact:

Justin Heath

PR Consultant on behalf of Power Roll

Resonates

Tel: +44 7760 263269

Email: powerroll@resonates.com