Seaweed offers unique potential to tackle microplastics and boost coastal economies

Published:

Read Time: 2 mins

Speaking at Wales’ first Festival of Seaweed, Dr Alex Newnes – co-founder and COO at PlantSea – explained how seaweed can replace plastic packaging to tackle microplastics, reduce carbon and contribute to a resilient green economy.

PlantSea is an award-winning start-up based in St Asaph. The founders, Alex Newnes, Gianmarco Sanfratello and Rhiannon Rees met at university of Aberystwyth, where they pioneered a seaweed-based flexible film that holds both liquids and dry products. The film is 100 per cent biodegradable and can be used as a replacement for plastic laundry pods.

Newnes said: “Some estimates suggest there could be one billion* water-soluble laundry and dishwasher pods used in the UK each year. These break down into tiny particles, resulting in around 1,000 tonnes of plastic dissolved into our water systems. Microplastics are making their way into our food and even into breast milk. Instead, we want healthy oceans and clean, plastic-free water and food chains – by thinking differently, we can have a big impact. Seaweed offers a biodegradable, compostable alternative.”

Wild seaweed harvesting is strictly controlled under quota, while aquaculture seaweed is grown from spores provided by native hatcheries within a specified range of where the seaweed will be grown. Seaweed cultivation results in carbon sequestration during growth, as well as providing habitats for native marine life.

A thriving, renewable aquaculture could also support employment in coastal areas typically suffering deprivation. However, according to Newnes, industry needs to scale up if we are to achieve the full economic benefit. He said: “Despite an ideal climate and extensive coastline, demand in the UK is low compared with other parts of the world. Many suppliers here lack high-volume customers to support growth, which is key to fostering job creation.”

PlantSea sources its seaweed from Scotland from both agricultural aquaculture and wild harvest. Since three university friends launched the business in 2020, it has won two prestigious Start-Up awards. The company now employs 10 people at its laboratory in St Asaph and hubs in Liverpool and London.

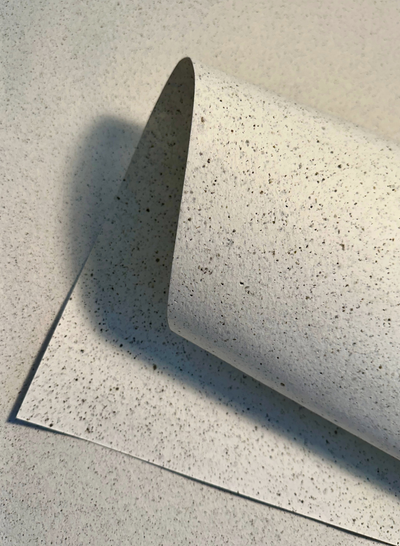

As well as manufacturing its plastic-replacement film, PlantSea produces paper and card packaging that incorporates waste seaweed. This product can be recycled in a standard paper mill and, in 2024, it became the first seaweed-based packaging to receive the OPRL Recycle label.

Dr Newnes appeared at Wales’ first Festival of Seaweed, in St Davids. The festival ran from 16–19 May and featured industry experts, conservationists, politicians, investors, educators, fishers, farmers and foodies.

* https://www.statista.com/statistics/302319/liquid-detergents-for-fabrics-usage-frequency-in-the-uk/

Ends

Editors notes

- PlantSea is a pioneering start-up that has developed a seaweed-based alternative to plastic film. It was established in 2020, when three PhD students joined forces to develop a solution to the global plastic crisis.

- Information released at the UN Oceans Conference** tells us that at least 11 billion tonnes of plastic end up in the sea every year. Plastic is predicted to outweigh fish in the ocean by 2050.

- It is estimated that we consume up to 250g of microplastics every year – that’s the equivalent of a credit card every week. And 83 per cent of our tap water contains microplastics.***

- In 2023, PlantSea, clinched two prestigious awards in a single evening. The company was honoured with the esteemed Enterprise Investment Scheme Association (EISA) Award and the coveted Start-up Award for North Wales.

**https://www.un.org/en/conferences/ocean2022/facts-figures

***https://wwf.org.au/news/2019/revealed-plastic-ingestion-by-people-could-be-equating-to-a-credit-card-a-week/