Creating nature’s own pest controllers: An exclusive look behind the scenes at Nemasys’ nematode production facility

Published:

Read Time: 7 mins

When it comes to pest control in the garden, beneficial nematodes are the go-to product for an organic and biodiverse-friendly approach. Each year, more gardeners are realising the efficacy of these small-but-mighty “worms”, that target and destroy problematic pests to safeguard and protect precious plants and crops, while causing no harm to other beneficial insects and pollinators. But many do not know the rigorous, thorough, and careful process that takes place to get these organically compatible pest controllers delivered fresh to the customers’ door.

Nemasys is the UK’s only nematode producer, with its production factory situated in Littlehampton, Sussex. It is the largest nematode production facility in the world and has been based at the same location for over thirty years.

Here, Nemasys Site Manager Doug Shewell and Production Manager Matt Clarke share some insight into the intricate process of creating these microscopic worms and how the future is looking for beneficial nematodes.

So, what exactly are nematodes?

“Nematodes are microscopic creatures that act as parasites on other insects. They occur naturally in the soil and seek out specific pests as prey,” explains Doug. “Our job is to take these microscopic organisms and multiply them through a careful and precise process so they can be applied into the garden to banish plant-devouring pests.”

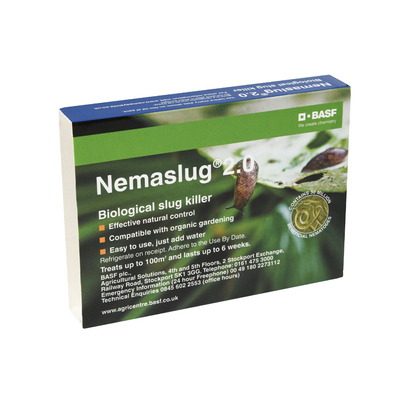

Beneficial nematodes come in a variety of species, each with different target prey. The most popular of the Nemasys collection, Nemaslug, is an effective and biological defence against slugs, whereas other species target pests such as vine weevil, caterpillar, leatherjackets and ants. Nematodes have been widely used in professional gardening and agricultural settings for years, but their popularity amongst amateur and home gardeners’ is now booming.

“Nematodes are not a new concept,” Matt adds. “Nemasys nematodes have been on the market and available for thirty years now. It is through our continuous efforts to educate and inform people on their benefits that their use has increased in line with the increasing demand for biological, organic-gardening friendly products.”

How are nematodes produced?

The production process begins by passing the chosen nematode species through its target prey to prove its efficacy, as only the most active and effective worms are used in Nemasys products. This nematode species is then mixed with a bacterium in sterile containers, which is specific to the nematode type to encourage development. The conditions within the containers are controlled based on the species requirements, with particular care taken regarding the temperature and nutrients. With the correct conditions and care, the nematodes will begin to multiply, and once maturity is reached, they move onto the fermentation stage.

Looking a little like a brewery, the site has over 190,000 litres of fermentation capacity, with each fermenter specification being adapted to the differing needs of each specie. Each machine offers different conditions and environments, including various internal temperatures and dissolved oxygen levels as this helps to maximise the growth of the nematodes and makes sure they develop strong and effectively.

The contents are then transferred to a sterile production vessel, with the largest tank being 75,000 litres, enough to produce over 8 trillion nematodes per run. The fermentation process can take up to 28 days depending on the species.

The nematodes are then transferred to wash tanks where they are kept cool and are cleaned to remove any remaining liquid. They are then ready to be package and are paired alongside a bespoke powder which helps maintain the nematodes stability and quality. Once sealed, they are immediately refrigerated until ready for dispatch across Europe, the US, Canada and the UK.

Which part of the entire process is most crucial?

“With any biological or microbiological process, whether its bacteria, fungus or nematode, you want to start with a healthy specimen,” advises Doug. “From day one when you isolate a singular nematode from a slug, through to the eight hundred billion that you end up with, the healthier the batch, the stronger and more effective the product. But that is where the challenge lies; the beginning of the process is crucial. You need to make sure you have the correct species, the right isolate, and you then just continue to nurture it throughout – any change can impact the end result.”

“Effectively, what we’re doing is re-enacting the natural process of reproduction but on a much larger scale. We must create an environment that exists for the nematodes when they are applied in the garden and target pests. The nematode will enter the slug, multiply and die back. But we have to upscale and maintain this quality, because you can sell fifty million nematodes, but they need to be fifty million nematodes that do their job, and this is something that Nemasys is dedicated to, making sure that every one of those fifty million nematodes work. This process can take over seven months for some species, so it’s a long, arduous journey.”

What do you find the most interesting about them?

“That they work! It continually amazes me that we can take something from nature, mass produce it, and it still works as nature intended,” says Doug. “I think what definitely interests me the most is learning how difficult it truly is to do this and to end up with an end product that does exactly as you want it to. And at Nemasys, quality is a key priority, so if the batch does not pass our requirements, it cannot be sent to customers – we know our product works and we want to make sure this is always the case.”

Matt agrees and adds; “The fact we also start with one specimen, and nurture it until it ends up as eight hundred billion of them is also pretty incredible! But as Doug said, hearing stories from customers about how well they have worked is always a highlight to us. We know that they work, but it means a lot more to hear the success stories from end-users.”

How is Nemasys working towards a more sustainable practice?

“By its very nature, the product is naturally sustainable,” says Doug. “It’s naturally occurring in the environment; we’re just supplementing this. The nematodes we produce are not harmful to animals, humans or beneficial bugs like bees and ladybirds, and they are also not harmful to the wider environment – so they already are a sustainable and biodiverse friendly product.”

“Looking away from the actual product, even the sleeve and container is sustainable, and can be recycled” adds Matt. “Nemasys beneficial nematodes are also the only nematode produced in the UK, so they do not need to travel far to end up with the end-user.”

To further its sustainable credentials, Nemaslug 2.0, which launched in 2023, contains a new species of nematode – Phasmarhabditis californica. This nematode can be packed at much higher concentrations, which has helped Nemasys to reduce the plastic packaging of its slug control solution by half. More efficient product storage as well as fewer containers being needed to transport the product has further reduced the carbon footprint.

On top of this, improvements made to production has led to a further reduction of over 20 tonnes of CO2 emissions a year, while the UK-based facility negates the need for carbon-heavy international shipping.

Do you think the demand for biological control will increase?

“I’d like to think so, but it is not as simple as yes or no,” admits Doug. “Ten years ago, we were already noticing more people turn away from chemicals, but people still use them and it’s not about banning them all together, but being responsible with how we use it. This is particularly true for wider agricultural professionals, as well as at home gardeners. In an ideal world, using no chemicals would be preferred, but it’s about balance and educating people on responsible use but also about being aware of chemical-free alternatives which might work better, like in this instance, nematodes.”

To find out more about nematodes, or to explore the entire range by Nemasys, visit the website at https://www.nemasysinfo.co.uk/en/Products/Overview/

If any journalists or writers would be interested in visiting the Nemasys production factory for a guided tour, please get in touch with Dani Hawkins at danihawkins@honestcommunications.co.uk

Ends

Editors notes

Nematodes are naturally occurring microscopic worms, already present in our soil. Beneficial nematodes attack and kill targeted garden pests. They are compatible with organic farming, easy to use and can even be kept in your fridge!

Research scientists have isolated the nematodes that kill specific garden pests including Slugs, Vine weevils, Leatherjackets, Caterpillars, Codling moth and much more.

BASF’s state of the art production facility in the UK produces billions of nematodes in a form that is easily applied by gardeners. Over 20,000 different species of nematodes have been classified, although some estimates put the total figure closer to one million! BASF has the largest specialist nematode production facility in the world, growing trillions of beneficial nematodes for use in their Nemasys range of pest control products.

BASF experts are available for interviews, features and expert comment on biological pest control management, and product is available for reviews, competitions and product trials.