Focus on the Oven Floor for Top Quality Wood-fired Gourmet Pizza

Published:

Read Time: 4 mins

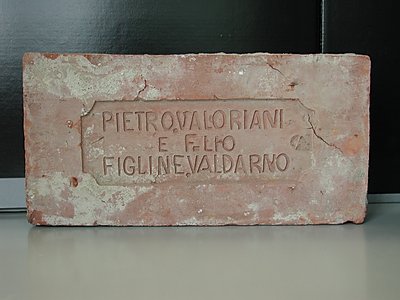

If restaurants want to serve their customers the best-quality pizza, they need to take to the floor and quick-step their way to better customer satisfaction rates. This is the view of commercial woodfired, gas-fired and electric pizza oven supplier, Orchard Ovens, which offers authentic Tuscan pizza ovens manufactured by Valoriani, strictly focused on quality pizza production.

Orchard Ovens says many restaurants and other eateries who are buying commercial pizza ovens focus too much on aesthetics and too little on the fundamentals of ensuring high-quality pizza oven performance. The oven floor is the key fundamental, as without a high-quality floor, no pizza oven can create authentic, first-rate pizza.

The composition and thickness of the pizza oven floor are critical factors when it comes to pizza cooking performance. A thicker oven floor absorbs and retains more heat, ensuring consistent cooking temperatures for extended periods during service.

The refractory clay, or cotto clay used by Valoriani to create its floor, is a special blend that creates a premium construction material for a pizza oven floor. The material helps distribute heat evenly across the floor, creating a cooking surface for pizza which is free of cold spots. In fact, the only spots in evidence are the perfect leopard-style spots that appear on the pizza crust, as it is cooking.

The blend used for a Valoriani wood-fired pizza oven floor is a proprietary mix of clay, alumina and natural minerals, rich in silica and aluminium oxide, which enhances durability. This blend provides high thermal mass but is also porous enough to absorb and distribute moisture. This makes it perfect for Neapolitan-style pizza and the high-hydration dough used in this very specific style of pizza cooking.

However, Valoriani manufactures floors to different blends, according to the style of pizza the check wishes to serve, with some ovens being specifically manufactured for baking bread, so the floor is there to support the individual menu.

The Valoriani refractory clay also recovers quickly between pizza cooking sessions, allowing the oven to cook back-to-back pizzas, to the speed that a commercial operation requires, if it wishes to keep its customers happy and the number of covers high.

The clay is highly durable and resistant to cracking. Unlike other oven floors, a Valoriani floor will not degrade quickly under intense heat. In fact, Valoriani ovens are still going strong in many commercial pizza environments twenty years after installation.

Contrast all of this with a thin oven floor, or one manufactured from inferior material. This cools down too quickly, impacting on the cooking of pizza and also requiring much longer periods of heat recovery. The latter could disrupt service and keep customers waiting for far too long.

In Valoriani’s case, the thickness of the oven floor is carefully controlled and typically 30-50mm in depth, according to model. The clay is shaped by artisans, in the Valoriani factory in Regello, Tuscany, and moulded into precision-cut slabs or tiles. Moulded clay is allowed to air-dry slowly, reducing its internal moisture prior to firing. This helps prevent cracks and structural weaknesses in the finished product.

Dried clay is fired in kilns at extremely high temperatures (over 1000°C). This vitrifies the material and gives it its high heat-resistance capacities, optimising the environment for pizza baking. Controlled firing in the kiln also ensures thermal shock resistance, so the floor will not crack under intense heat fluctuations. Strict quality control is exercised over each batch, to check for cracks and density consistency.

So if you want to strictly turn out top-quality pizza, you need to keep your feet on the gorund and concentrate on your oven’s floor. Do that and you should be waltzing towards a profitable pizza enterprise based on good quality products and high levels of diner satisfaction.

To find out more about the models that feature this authentic Tuscan refractory clay floor, call Orchard Ovens on 07743 847647 with your commercial pizza oven enquiry.

Ends

Editors notes

Orchard Ovens is the domestic and commercial pizza oven supplier in the UK of Valoriani, based in Reggello, Tuscany - the manufacturer of Italy's hugely respected Valoriani pizza ovens, known as the Maserati of pizza ovens and the kings of clay. These ovens are made from superb refractory clay - cotto clay - found in the family's quarry and unique, thanks to having just the right alumina. This allows Valoriani ovens to heat up quickly and retain heat superbly, bring huge advantages to homeowners, as well as restaurant owners, hotels, pubs, mobile caterers, pizzerias, takeaways and more.

Orchard Ovens supplies some of Britain's best-known restaurants and chefs, whilst it is also a specialist creator of outdoor kitchens and wood-fired oven builds for the rich and famous, as well as everyday homeowners wishing to add value to their home and enjoy an outdoor lifestyle to the full.

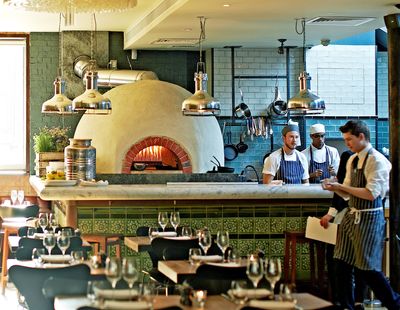

A commercial wood fired Valoriani pizza oven, supplied by Orchard Ovens, in a fast food retail environment/takeaway operation.